The cost of supply chain issues add up quickly. Financial costs may include higher cost of substitute products, increased waste, readmission penalties or absenteeism.

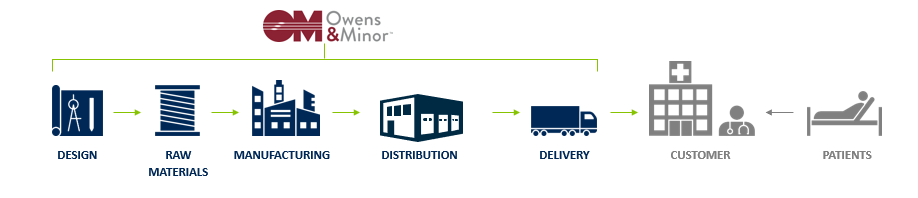

Owens & Minor strives to

simplify the process so

you don't have to worry

about it.

Our vertically integrated

supply chain makes our

process better.

- Design products and their specifications to ensure appropriateness for use

- Select the best raw materials

- Self-manufacture most of our products, many in North America

- Apply high quality standards

- Have three strategically-located distribution centers in North America for rapid deployment

We are equipped for the

unpredictable.

Reliability means being prepared to respond better to

things we can't control, such as:

- Hurricanes Harvey and Irma disrupting the flow of inventory

- 2015 port strike halting shipments from Asia to the west coast

Up to 8 weeks for shipment from Asia

2 weeks (or less) for Owens & Minor response.

Reliability starts with being carefully made.

World-Class Facilities

- Standardized, proprietary processes

- Manufacturing in US, Mexico, Honduras and Thailand

- Reliability across locations

Clinically Superior Products

- Patented, proprietary products

- Control over raw material selection

- Numerous quality checkpoints

- Reliability in every product category

Engaged Workforce

- In-house labor force

- Workforce initiatives focused on safety, sustainability, and community involvement

- Reliability through a stable work force

O&M Global Products' reliability gives you complete peace

of mind without costing you more.

The Promise

Competitors promise 30% savings on sterilization wrap, which sounds very attractive on the surface.

Apples to Oranges

But competitors offer savings based on providing lower quality products. They offer five grades of wraps, where Halyard provides seven.

Poor Performance = Reprocessing Costs

An increase of just 2% in tears, cuts, and holes as a resultt of substituting lower-grades can wipe out any potential savings.

Adding Expensive Accessories

Customers then buy corner protectors and other expensive accessories to try and make the lesser wrap “work.”