How Environmental Considerations Influence Owens & Minor’s Production Process

As governments, businesses and individuals around the world strive to mitigate the effects of a changing climate, reducing environmental impact is a shared goal. Owens & Minor is contributing to these efforts through a range of initiatives including proactively reviewing its operations and supply chain for climate-related threats and opportunities, reducing emissions, minimizing waste, conserving water and committing to circular manufacturing principles wherever possible.

Its Safeskin glove manufacturing facility in Thailand is no exception. As of 2023, the facility has reduced total water usage by 5.5%, as compared to 2020, despite an increase in manufacturing. It has implemented an environmental management system to meet ISO 14001:2015 and has received three Green Industry Level 5 certifications since 2015 by the Ministry of Industry in Thailand. It also maintains a recycling rate of more than 95%

A HISTORY OF SUSTAINABILITY AND POSITIVE IMPACT

The Owens & Minor Safeskin facility is a testament to the company’s commitment to sustainability. Latex gloves are formulated from latex sap, a soft hite substance found beneath the bark of rubber trees. The facility operates on 92% renewable energy by using rubber tree wood as the sole biomass fuel in its wood boilers. The practice embodies a circular and sustainable manufacturing process that aligns with Owens & Minor’s Environmental, Social, and Governance (ESG) focus areas (Promoting Environmental Stewardship; Caring for Our Customers & Communities; Operating Responsibly; and Empowering Our Teammates).

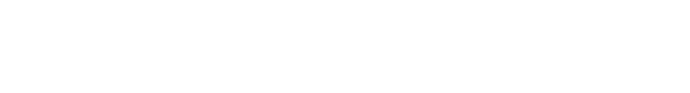

Rubber Tree Fast Facts

- Approximately 5-6 years after a tree is planted, it begins to produce valuable latex sap, which is continuously extracted throughout the tree’s lifetime.

- Small incisions in the bark allow for sap extraction, a process that does not harm the trees.

- Once the trees reach the end of their sap producing lifecycle, they are cut down and repurposed as wood pellets, logs and chips – which are used in many ways, including as fuel in wood boilers.

All wood pellets, logs, and chips used at the Safeskin facility are sourced exclusively from local rubber trees – a truly renewable resource. After approximately 30 years, when the trees stop producing sap, the wood is repurposed as fuel for manufacturing processes and new trees can be planted – restarting the lifecycle once again.

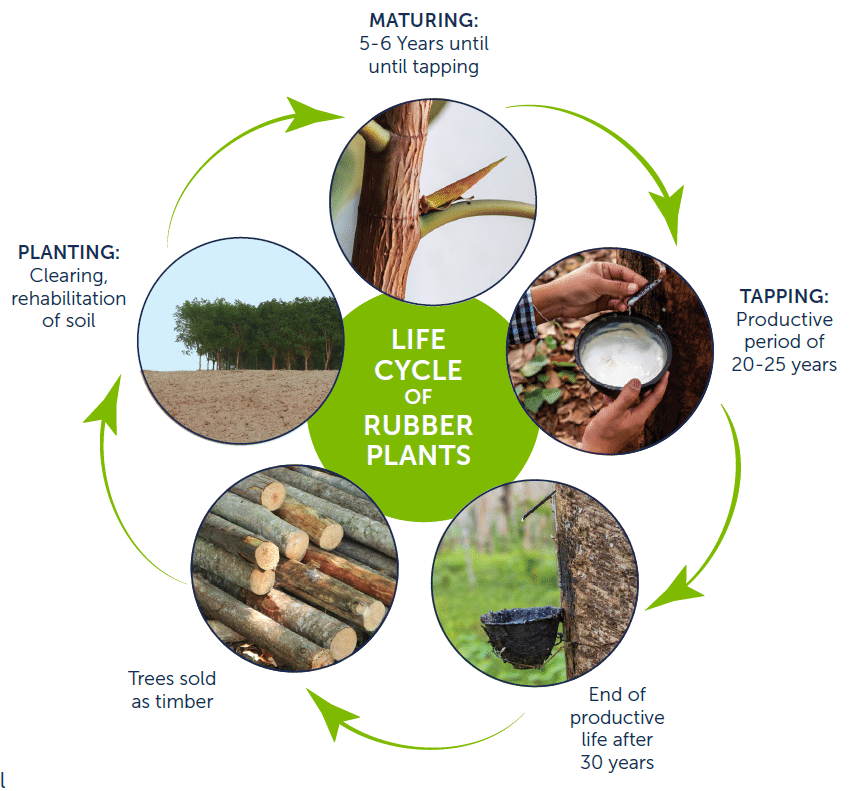

THE WOOD BOILER PROCESS:

HARNESSING RUBBER WOOD FOR ENERGY

At the Owens & Minor Safeskin facility, wood pellets, logs and chips obtained from rubber trees are used to fuel wood boilers, generating heat to produce steam. The steam is then channeled to the production lines for glove processing. The use of wood biomass as a fuel source is carbon neutral, which allows for responsible operations supporting Owens & Minor’s sustainability initiatives.

Behind the Innovation

Managing the wood supply to minimize environmental impact is a complicated process, but with decades of expertise, Owens & Minor is well-equipped to meet these challenges. For example, wood branches must be aged 30-40 days before use and must be delivered on racks, in a process known as racking. To ensure that the wood meets its standards, the Safeskin plant sources the trees and inspects the dried wood for moisture before transporting it to the boiler area.

Safeskin works with local suppliers to confirm that they have the space to store up to 40 days of aged wood inventory and the ability to supply wood chips and pellets with consistent quality, a process that can be particularly challenging during rainy season. Safeskin also provides training to suppliers to make sure they adhere to its environmental health and safety standards.

EFFICIENT USE OF RESOURCES

Safeskin utilizes every part of the rubber tree wood, including the waste from the wood boiler operation. The rubber wood ash, generated from the boiler, is recycled and reused. Occasionally, the ash is mixed with rice husk and poultry manure to produce a non-chemical fertilizer, which Owens & Minor periodically distributes free-of-charge to local farmers in Thailand in cooperation with the local Land Development Department. This process is subject to the approval by the Land Development Department and the needs of the farmers. Due to the high quantity of wood boiler ash generated, not all will be consumed for the fertilizer project. The wood boiler ash balance which contains charcoal content, is sent to cement plants to be used as alternative fuels and raw materials in cement processing. This closed-loop system ensures that the rubber trees are utilized efficiently and sustainably. Currently, all wood boiler ash is recycled through the cement factory.

The Steam Generation Process

SUSTAINABLE EXCELLENCE:

HALYARD* PUREZERO* HG3 LATEX GLOVES

Owens & Minor’s track record of sustainable latex glove operations and its forward-thinking approach exemplify its commitment to delivering innovative solutions responsibly. The new HALYARD* PUREZERO* HG3 Cream Latex Gloves are a prime example of a high-quality solution, designed and produced with sustainability at the forefront. For more information on HALYARD* PUREZERO* HG3 Cream Latex Gloves, please visit https://products. halyardhealth.com/halyard-purezero-hg3- white-nitrile-gloves