PUREZERO* Cleanroom Gloves

From HALYARD*, manufacturers of Cleanroom and Life Science Gloves for over 20 years.

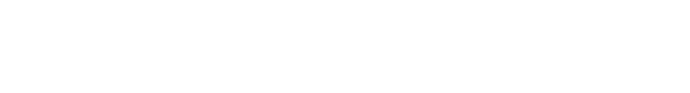

HALYARD* offers an accelerator-free1 portfolio of three non-sterile and two sterile cleanroom gloves to address the needs of Pharmaceutical, Medical Device, Microelectronics and Semiconductor Manufacturing.

MANAGE YOUR CLEANROOM RISKS

Your gloves have a big job to do, protecting your workers as well as your product and your process. Plus you need a reliable supply to avoid operations disruption. That’s why we created HALYARD* PUREZERO* Cleanroom Gloves.

PUREZERO* Cleanroom Gloves are ideal for applications that involve handling delicate equipment in microelectronics, semiconductors, optics, pharmaceutical and medical device manufacturing applications. In fact, they are specifically designed to meet the stringent requirements of cleanroom environments.

New PUREZERO* gloves are designed to exact standards, to help you manage:

- the risks associated with user comfort and protection

- product contamination

- supply chain resiliency

PUREZERO* HG3 WHITE NITRILE GLOVES

Recommended for use in ISO Class 3 or higher and Grade A/B/C/D cleanrooms and have a max particle count of 950 > 0.5μm/cm2.

PUREZERO* HG3 White Nitrile Cleanroom Gloves are 12 inches long and feature a beaded cuff to aid in donning and help prevent roll down. Available in 2 Accelerator-Free1 options.

Non-Sterile

White Non-Sterile cleanroom gloves:

- Have a high tack/tacky grip and textured fingertips

- Ambidextrous

- Available in sizes XS – XL

Sterile

White Sterile cleanroom gloves:

- Have a smooth grip and textured fingertips

- Hand specific

- Available in sizes 6.0 – 9.0 and 10.0

VIEW STERILEDONNING & DOFFING VIDEO

VIEW NON-STERILEDONNING & DOFFING VIDEO

PUREZERO* CLEANROOM GLOVE PORTFOLIO

Download the HALYARD* PUREZERO* Cleanroom Gloves Brochure to learn more about how to protect your cleanroom processes and staff from harmful contamination.

Download the HALYARD* PUREZERO* Behind The Innovation brochure and learn how we have been manufacturing cleanroom gloves for 20+ years

PUREZERO* HG3 LIGHT BLUE NITRILE GLOVES

Non-Sterile & Sterile Available

Recommended for use in ISO Class 3 or higher and Grade A/B/C/D cleanrooms and have a max particle count of 1200 > 0.5μm/cm2.

PUREZERO* HG3 Light Blue Nitrile Cleanroom Gloves are 12 inches long and feature a beaded cuff to aid in donning and help prevent roll down. Available in 2 Accelerator-Free1 options.

Non-Sterile

Light Blue Non-Sterile cleanroom gloves:

- Have a tacky grip and textured fingertips

- Ambidextrous

- Available in sizes XS – XL

Sterile

Light Blue Sterile cleanroom gloves:

- Have a smooth grip and textured fingertips

- Hand-specific

- Available in sizes 6.0 – 9.0 and 10.0

THE RISK: USER COMFORT AND PROTECTION

The accelerator-free1 formulation of PUREZERO* Nitrile Cleanroom Gloves is the solution. It reduces the risk of allergies and skin irritation associated with accelerator chemicals in other nitrile gloves. As a result, PUREZERO* gloves are comfortable to wear, allowing workers to focus on their delicate tasks rather than their gloves.

PUREZERO* Cleanroom Nitrile Gloves are designed to protect workers with effective barrier protection against chemical splash, micro-organisms and viruses.

PUREZERO* are PPE Category III certified according to the following standards:

Compliant to these regulatory standards:

- ISO 9001

- ISO 13485

- ISO 14001

Compliant to these food handling regulatory standards:

- FDA 21 CFR 177-2600

- FDA 21 CFR 180.22

Commission Regulation (EU) No 10/2011

- CE 2797 PPE Category III according to Regulation (EU) 2016/425 EEC

- EN 16523-1:2015+A1:2018

- EN ISO 374-2:2019

- EN ISO 374-4:2019

- EN ISO 374-5:2016 Bacteria, Fungi, and Virus Protection

- EN ISO 374-1:2016+A1:2018/ Type B

- EN ISO 21420:2020 Dexterity Classification: Level 5

Compliant with the REACH regulation

- RoHS 2011/65/EU Annex II

- Static Dissipative in Use

- Tested per ANSI/ ESD SP 15.1

Meets USP <800> Guidelines

THE RISK: PRODUCT CONTAMINATION

The solution is the consistent quality of PUREZERO* Cleanroom Gloves, ensuring low particle and endotoxin levels. HALYARD* PUREZERO* Gloves are manufactured and packaged at our ISO 9001 facility in state-of the-art cleanrooms and are recommended for ISO 3 cleanrooms or higher. Our gloves are clean processed (washed repeatedly in deionized water) to ensure consistent control of low particles, extractables and endotoxin levels.

- Low Particle Levels (max 950 > 0.5μm/cm2 for white gloves, max 1200 > 0.5μm/cm2 for blue gloves)

- Sterility Assurance Levels (SAL) of 10-6 and an endotoxin level of 20 units/pair maximum

- AQL of 1.0 for pinholes

- Double bagged plus case liner

You can rely on consistent quality, with Certificates of Analysis (CoA), and Certificates of Irradiation (CoI) easily accessible online for every production lot. You can also find the Declaration of Conformity (DoC) documents showing compliance to applicable regulations and standards, click the link below to find the information you need.

THE RISK: SUPPLY CHAIN RESILIENCY

PUREZERO* Cleanroom Gloves are the solution, ensuring reliable supply, regulatory compliance and consistent quality.

HALYARD* has manufactured private label cleanroom gloves for more than 20 years at our Safeskin Medical & Scientific (Thailand) Ltd. manufacturing facility, which holds ISO 9001 and ISO 13485 certifications. We control the materials and design while adhering to strict quality standards and product specifications in our own facilities, with our own teammates. Quality and sterility assurance levels are guaranteed, with all raw materials and components traceable to their original supplier. And with our global product codes, you can use one code/SKU from HALYARD* globally at all of your production facilities.

RISK-FREE CONVERSION

With our years of cleanroom glove experience, HALYARD* can provide all the support you need to easily convert from your current glove to new PUREZERO* Cleanroom Gloves, including:

- Technical documentation

- Validation data

- Product knowledge and expertise

We also have the manufacturing capacity to assure reliable glove supply going forward.

Tracking of gloves by lot and batch number from the glove manufacturer is critical to ensuring compliance with Good Manufacturing Practices per ISO Standards.

Technical Documentation

Resources

Questions & Sample Requests

Sources

1 Not formulated with these commonly used vulcanizing chemicals: Sulfur, Thiurams, Thiaxoles, Guanidines and Carbamates.

2 Tested per ASTM D6319, EN 455-2

COPY-05022