PUREZERO* - Behind the Innovation

Many common products — from smartphones to medical devices to medications — must be manufactured in cleanroom environments. Because these products are delicate and in some cases potentially harmful to those handling them, cleanrooms are highly controlled and regulate conditions such as air quality and flow, temperature and humidity.

Many common products — from smartphones to medical devices to medications — must be manufactured in cleanroom environments. Because these products are delicate and in some cases potentially harmful to those handling them, cleanrooms are highly controlled and regulate conditions such as air quality and flow, temperature and humidity.

The ultimate goal of a cleanroom is, of course, that it remains clean. There are different levels of “clean” that a cleanroom must adhere to, as determined by International Organization for Standardization (ISO) Standard 14664-1:2015. ISO identifies nine classes of cleanroom, and ISO 14664 contains 10 parts that outline standards for cleanroom elements such as air cleanliness by particle concentration, test methods, design, construction and start-up.

But it’s not enough for a manufacturer to design and build a cleanroom that meets the ISO standards of its determined ISO class. They also must consider that employees responsible for handling materials while in the cleanroom – whether chemicals, microchips or medical devices – can introduce particles into the environment from their skin or non-cleanroom clothing, or even from the personal protective equipment (PPE) they wear while in the room.

Knowing your class of cleanroom is important and can influence the type of PPE that you will need, which typically includes:

Knowing your class of cleanroom is important and can influence the type of PPE that you will need, which typically includes:

- Gloves

- Hoods

- Caps

- Helmets

- Coveralls

- Overboots

- Face masks

- Goggles or safety glasses

According to ISO Standard 14664-5:2004, “the best design of cleanroom clothing will completely envelop the wrist, neck and ankle”. The same standard outlines PPE’s barrier and electrostatic properties, durability, and design. For example, to minimize contamination risks, PPE should not incorporate pockets, pleats, darts, hook and pile fasteners, and any elasticized or knitted cuffs should not trap contaminants or build up an electrostatic charge.

A FOCUS ON THE HANDS

Special attention should be paid to gloves, as almost all classes require them and they are the piece of PPE that covers the part of the body closest to the given product and working surfaces. For employees working in aseptic pharmaceutical cleanrooms where they may be handling medicines or chemicals, it is especially important to ensure sterility and protection. For those working in semiconductor cleanrooms handling sensitive electronics, it’s important to have a glove that has low particle counts, such as HALYARD* PUREZERO* Nitrile Gloves, which guarantee low particle counts (max 950 > 0.5μm/cm2 for white gloves, max 1200 > 0.5μm/cm2 for blue gloves).

Cleanroom managers should consider the properties of their cleanroom glove based on the ISO class of the room and what they are making, including surface contamination, sterility, tactility, strength, comfort, fit and how they are packaged. They should also consider the material, which can have implications for worker safety.

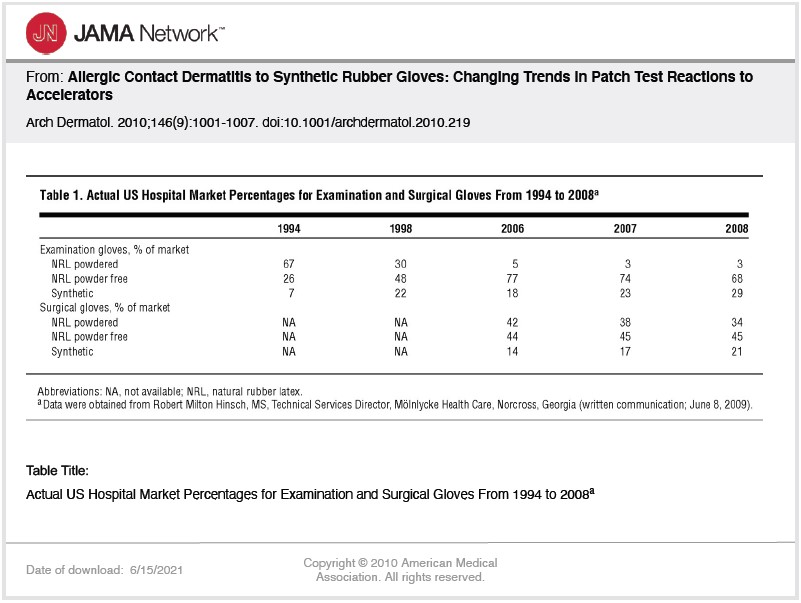

Nitrile gloves offer added protection against chemical splash, micro-organisms and viruses. But nitrile, and other non-latex gloves can cause Type IV skin allergies in some workers, which are typically attributed to Sulphur-based chemical accelerators (predominantly thiazoles, thiurams and carbamates) that are used to ensure a rapid vulcanization of the polymers in nitrile or other non-latex exam gloves. These chemical allergies represent approximately 30 percent of occupationally induced skin diseases — and it is the second largest occupational disability reported to OSHA.

Therefore, cleanroom manufacturers may want to consider a glove such as HALYARD* PUREZERO* Nitrile Gloves, which are manufactured with an accelerator-free formulation.

CHOOSE THE RIGHT MANUFACTURER

Given the fact that there is little room for error in cleanroom environments, manufacturers need to consider what a given glove manufacturer offers in terms of features, product safety and supply chain reliability. Finding one that can meet all three areas in addition to creating a product that meets a manufacturer’s particle count and endotoxin level requirements is critical. Of course, experience is important but it’s also ideal that the glove manufacturer have complete control over their supply chain – helped by owning their own production facility – with the ability to have documents readily available online like Certificates of Analysis and Certificates of Irradiation.

Having a safe and reliable supply of PPE that meets the standards of your ISO cleanroom class is an essential part of maintaining worker and product safety, product functionality and, in some cases, patient safety. So cleanroom manufacturers are encouraged to give their product decisions careful thought and to choose a PPE manufacturer who can be a partner in their success.